Home > Company Introduction

Company Overview

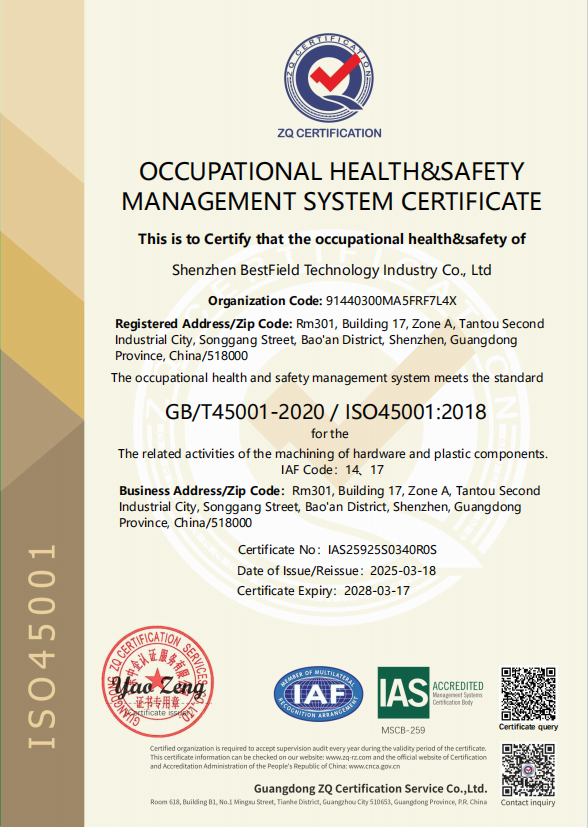

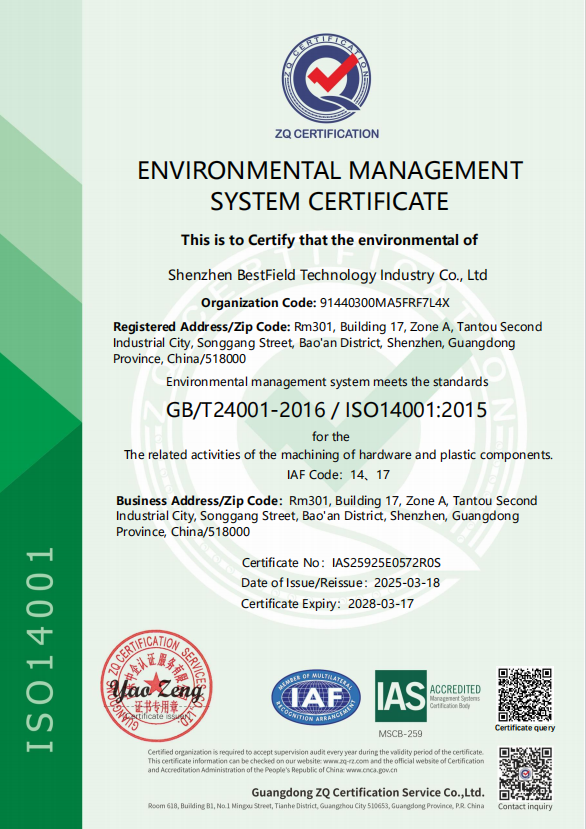

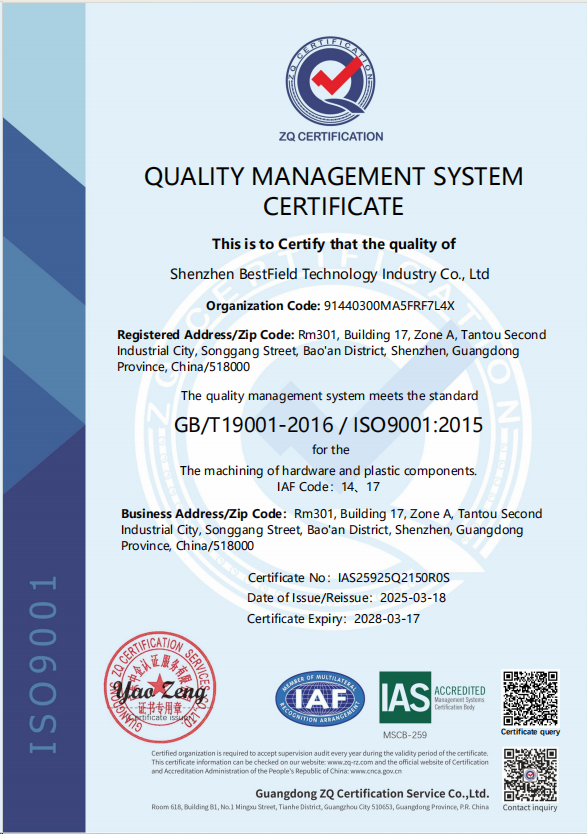

Shenzhen BestField Technology Industry Co., Ltd Precision Manufacturing Partner for Automotive, Aerospace & Medical Innovations Headquartered in Shenzhen, China | www.bestfield.ltd Why Global Leaders Choose Us? Zero MOQ, Zero Compromise: From 1-piece prototypes to 10,000 mass production – no order too small, no deadline too tight. Ultra-Fast Turnkey Solutions: 1-3 day rapid delivery & 24/7 quote response – slash your time-to-market by 70%. Mission-Critical Precision: ±0.005mm tolerances achieved through 5-axis CNC, sheet metal bending, and 3D printing. Certified Excellence: QES-certified with processes aligned toISO9001:2016 (Automotive) and ISO14001 (Aerospace) standards. Trusted by Industry Titans: Supply precision components for GE Healthcare, U.S. prosthetics leaders, and global automotive OEMs. Industry-Specific Expertise Automotive: EV battery housings, lightweight chassis parts (magnesium/titanium alloys), and high-volume production with 100% traceability. Aerospace: Complex avionics enclosures, instrumentation mounts, and mechanical assemblies – full material certification & RoHS compliance. Medical: Biocompatible prosthetics, surgical tooling, and 3D-printed implants with ISO 13485-ready quality systems. Your Guaranteed Advantage 1 00% On-Time Delivery: 98% client retention rate since 2020. 100% Quality Assurance: CMM inspection reports provided with every batch. 100% Flexibility: Scale production up/down within 48 hours – no penalties. Contact Us Now & Get a Quote in 24 Hours!

-

ManufacturerBusiness Type

-

2019Year Established

-

Below 1,000 square metersFactory Size

-

US$2.5 Million - US$5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

11 - 50 People Total Employees

-

1-10 People Sales Staff

-

5-10 People Quality Inspectors

-

ISO9001, ISO14000, Others Product Certifications

-

US$2.5 Million - US$5 Million Annual Export Value

-

North America, South America, Oceania, Mid East, Eastern Asia, Central America, Northern Europe, South Asia Main Markets

-

yantian Port of Shipment

-

CNC Machine Tools Main Industry

-

Quality ControlShenzhen BestField – Precision Built on Rigorous Quality Control At BestField, every component undergoes a 5-stage quality assurance protocol aligned with QES international standards: Material Verification Incoming metals and polymers are tested for hardness, composition, and traceability using spectrometers and ISO-certified supplier audits. In-Process Monitoring Real-time sensors on CNC/3D printing systems capture dimensional accuracy (±0.005mm), while engineers conduct on-machine CMM inspections to prevent deviations. Post-Processing Validation Sheet metal bends and surface finishes are verified via laser scanners and roughness testers, ensuring compliance with medical-grade specifications. Functional Testing Critical assemblies (e.g., prosthetics joints) undergo load cycling, corrosion resistance, and fatigue simulations in our lab. Traceability & Certification Each batch includes a digital QC report with 3D scan data, material certs, and compliance seals for FDA-aligned industries. Supported by 10+ QA engineers and a closed-loop feedback system, we achieve 99.2% on-time delivery with zero critical defects since 2021.

Quality ControlShenzhen BestField – Precision Built on Rigorous Quality Control At BestField, every component undergoes a 5-stage quality assurance protocol aligned with QES international standards: Material Verification Incoming metals and polymers are tested for hardness, composition, and traceability using spectrometers and ISO-certified supplier audits. In-Process Monitoring Real-time sensors on CNC/3D printing systems capture dimensional accuracy (±0.005mm), while engineers conduct on-machine CMM inspections to prevent deviations. Post-Processing Validation Sheet metal bends and surface finishes are verified via laser scanners and roughness testers, ensuring compliance with medical-grade specifications. Functional Testing Critical assemblies (e.g., prosthetics joints) undergo load cycling, corrosion resistance, and fatigue simulations in our lab. Traceability & Certification Each batch includes a digital QC report with 3D scan data, material certs, and compliance seals for FDA-aligned industries. Supported by 10+ QA engineers and a closed-loop feedback system, we achieve 99.2% on-time delivery with zero critical defects since 2021. -

Our ServicesShenzhen BestField Technology Industry Co., Ltd., headquartered in Shenzhen, China, is a precision manufacturing expert specializing in CNC milling/turning, 5-axis machining, and sheet metal fabrication. Equipped with advanced 5-axis CNC systems and high-precision bending machines, we deliver complex, tight-tolerance components for industries requiring exceptional accuracy. Certified with QES (Quality, Environment, Occupational Health & Safety) Management Systems, we ensure international standards in every project. Our rapid 1-3-day turnaround and 24-hour quotation response set us apart, enabling clients to accelerate product development and meet urgent demands. As a trusted partner to leading global brands, including a top U.S. prosthetics innovator, we provide precision CNC parts and sheet metal assemblies critical to medical and industrial applications. From prototyping to mass production, BestField combines cutting-edge technology, rigorous quality control, and customer-centric service to exceed expectations. Visit www.bestfield.ltd to explore how we empower your success with speed, precision, and reliability.

Our ServicesShenzhen BestField Technology Industry Co., Ltd., headquartered in Shenzhen, China, is a precision manufacturing expert specializing in CNC milling/turning, 5-axis machining, and sheet metal fabrication. Equipped with advanced 5-axis CNC systems and high-precision bending machines, we deliver complex, tight-tolerance components for industries requiring exceptional accuracy. Certified with QES (Quality, Environment, Occupational Health & Safety) Management Systems, we ensure international standards in every project. Our rapid 1-3-day turnaround and 24-hour quotation response set us apart, enabling clients to accelerate product development and meet urgent demands. As a trusted partner to leading global brands, including a top U.S. prosthetics innovator, we provide precision CNC parts and sheet metal assemblies critical to medical and industrial applications. From prototyping to mass production, BestField combines cutting-edge technology, rigorous quality control, and customer-centric service to exceed expectations. Visit www.bestfield.ltd to explore how we empower your success with speed, precision, and reliability. -

Company HistoryFounded in 2014 in Shenzhen, China, BestField began as a precision engineering workshop focused on CNC machining and sheet metal fabrication. Recognizing the growing demand for rapid prototyping and complex geometries, we integrated industrial-grade 3D printing into our capabilities by 2017, enabling hybrid manufacturing solutions that combine additive and subtractive technologies. In 2019, our investment in 5-axis CNC systems and automated sheet metal lines solidified our position as a multi-process manufacturer. The same year, we achieved QES certification, underscoring our commitment to quality, sustainability, and workplace safety. A pivotal milestone came in 2021 when we partnered with a leading U.S. prosthetics brand, leveraging our 3D-printed prototypes and precision-machined components to accelerate their R&D cycles. Today, BestField serves global clients across medical, robotics, and industrial sectors, offering end-to-end manufacturing – from 3D-printed prototypes to high-volume CNC production – all backed by 24/7 technical support and a 1-3-day delivery promise.

Company HistoryFounded in 2014 in Shenzhen, China, BestField began as a precision engineering workshop focused on CNC machining and sheet metal fabrication. Recognizing the growing demand for rapid prototyping and complex geometries, we integrated industrial-grade 3D printing into our capabilities by 2017, enabling hybrid manufacturing solutions that combine additive and subtractive technologies. In 2019, our investment in 5-axis CNC systems and automated sheet metal lines solidified our position as a multi-process manufacturer. The same year, we achieved QES certification, underscoring our commitment to quality, sustainability, and workplace safety. A pivotal milestone came in 2021 when we partnered with a leading U.S. prosthetics brand, leveraging our 3D-printed prototypes and precision-machined components to accelerate their R&D cycles. Today, BestField serves global clients across medical, robotics, and industrial sectors, offering end-to-end manufacturing – from 3D-printed prototypes to high-volume CNC production – all backed by 24/7 technical support and a 1-3-day delivery promise. -

Our TeamBestField’s success is driven by a 60+ member team of engineers, technicians, and operations specialists with 10+ years’ average industry experience. Our core R&D team holds certifications in 5-axis programming, additive manufacturing, and lean production, ensuring seamless integration of 3D printing with CNC/ sheet metal workflows. Dedicated quality control experts rigorously enforce QES standards across every project, while customer service specialists provide 24/7 bilingual support to guarantee rapid response and transparency. From prototyping to delivery, our cross-functional team combines technical mastery with a shared mission: to deliver precision, speed, and innovation that redefine manufacturing excellence.

Our TeamBestField’s success is driven by a 60+ member team of engineers, technicians, and operations specialists with 10+ years’ average industry experience. Our core R&D team holds certifications in 5-axis programming, additive manufacturing, and lean production, ensuring seamless integration of 3D printing with CNC/ sheet metal workflows. Dedicated quality control experts rigorously enforce QES standards across every project, while customer service specialists provide 24/7 bilingual support to guarantee rapid response and transparency. From prototyping to delivery, our cross-functional team combines technical mastery with a shared mission: to deliver precision, speed, and innovation that redefine manufacturing excellence.

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.